The TAM Air is an air-based thermostat, utilizing a heat sink to conduct the heat away from the sample and effectively minimize outside temperature effects. The high accuracy and stability of the thermostat makes the calorimeter well-suited for heat flow measurements over extended periods of time, e.g. weeks.

The isothermal (heat conduction) calorimetry is an efficient tool to study the stages related to the hydration of cement pastes or mortars at constant temperature. The calorimeter continuously measures and displays the heat flow related to the hydration reactions taking place in the cement paste after mixing. The heat flow is a measure of kinetic of hydration process. The degree of hydration is a fundamental parameter to study the reactivity of pure cement component, proportion of cement composition, the reactivity of the new cementitious materials.

Example of use: Heat flow and heat of hydration of cement paste applied in Tunnel

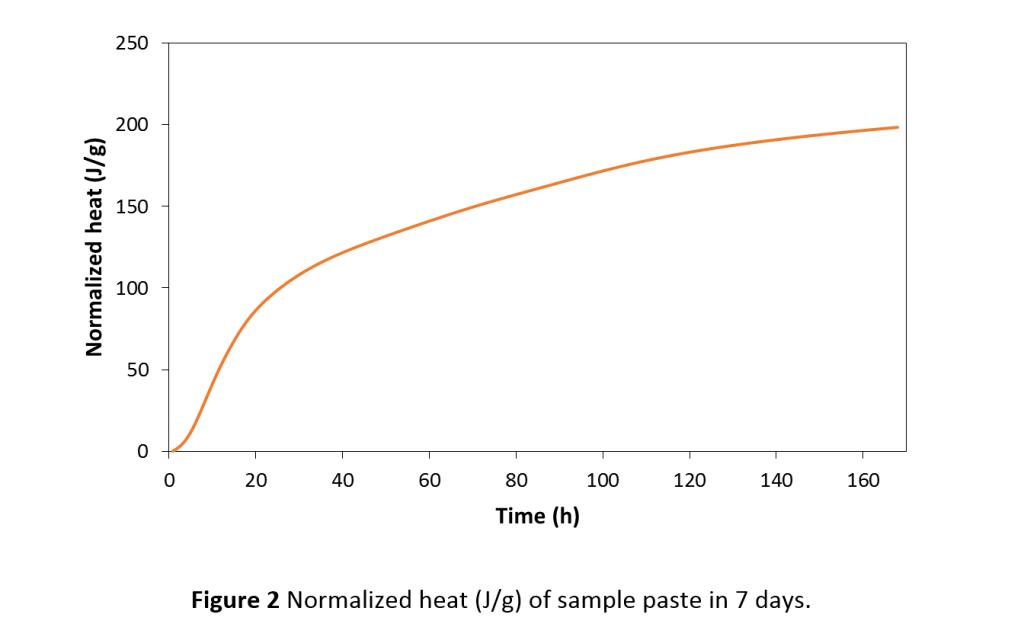

Cement hydration is an exothermic reaction that takes place in several phases, visible in the calorimetry curve:

- Rapid initial processes

- Induction period

- Acceleration period

- Period of retardation

- Prolonged reactions

Figure 1 shows the course of the reaction in the first 50 hours. The acceleration period is characterized by a major peak in the calorimetry curve, which is mainly attributed to the silicate reaction, i.e. the formation of C-S-H gel and calcium hydroxide (Ca(OH)2). Another slightly smaller peak can be observed, about 16 hours after the start of the reaction. This peak indicates dissolution of the aluminate (C3A) and subsequent formation of ettringite.